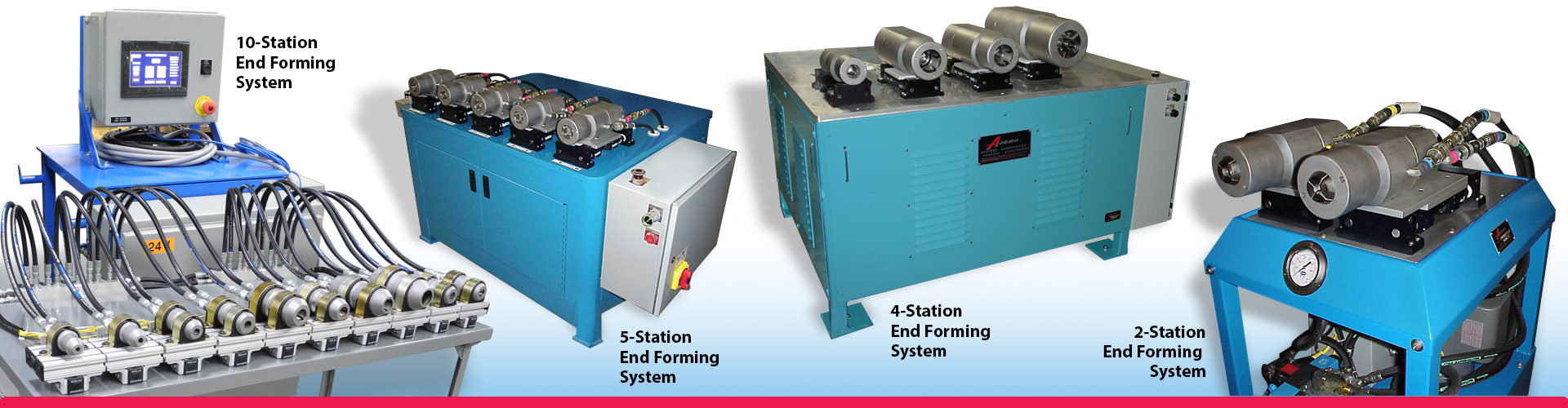

Multi-Station End Forming Systems

Engineered to your unique tube specifications

Pressures Up to 3,000 psi (207 bar)

Airmo Inc.® manufactures custom designed, multi-station tube end forming systems. These automated hydraulic machines integrate our Modular End Forming Tools to form a system that reduces production time on end forming tubes of several different dimensions or forms. Tooling is permanently mounted on semi-enclosed or enclosed stands which simplifies tube insertion for the operator during the forming cycle. Smaller units have casters for easy portability and large units are skidded for transfer with a forklift. Machines can be manually operated with push-button switches, or engineered with touch-screen digital displays.

Specifications | Description | |

| Maximum Pressure: | Working pressures up to 3,000 psi (207 bar) | |

| Electrical: | Tailored to electrical service used | |

| Temperature: | 32° F to 120° F (0° C to 49° C) | |

| Hydraulic Fluid: | 10 US gallon (38 liters) | |

| Valves: | 24 Vdc for safety | |

| Maximum Oil Flow: | .66 gpm (2.5 lpm) | |

| Digital Pressure Switch & Dwell Timer: | For setting hold time duration and activating tool retraction | |

| Cycle Time: | 2 seconds for small End Forming Tools | |

| Operation: | Powers SelectForm® End Forming Tools | |

| Noise Level: | System runs quietly | |

| Construction: | Portable system mounted on casters | |

| Systems: | Multiple stations built for application requirements |

Download Product Sheet

Multi-Station End Forming Systems

Engineered to your unique tube specifications

Pressures Up to 3,000 psi (207 bar)

Airmo Inc.® manufactures custom designed, multi-station tube end forming systems. These automated hydraulic machines integrate our Modular Ending Forming Tools to form a systems that reduces production time on end forming tubes of several different dimensions or forms. Tooling is permanently mounted on semi-enclosed or enclosed stands which simplifies tube insertion for the operator during the forming cycling. Smaller units have casters for easy portability and large units are skidded for transfer with a forklift. Machines can be manually operated with push-button switches, or engineered with touch-screen digital displays.

View End Forming Animation

View End Forming Animation