|

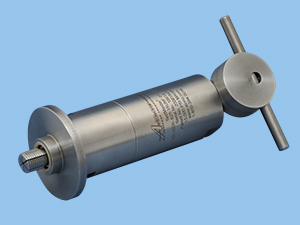

TestMaster® Model 350 Series Hydrostatic Bottle and Cylinder Test Tool

Decreases Thread Damage and Reduces Cost of Goods for Piper Metal Forming Company

Piper Metal Forming Corporation, a leading oxygen and carbon dioxide cylinder manufacturer, is among the first companies to realize the dramatic cost-saving benefits of the new Airmo TestMaster® Model 350 Series Hydrostatic Bottle and Cylinder Test Tool. Piper Metal Forming Corporation, a leading oxygen and carbon dioxide cylinder manufacturer, is among the first companies to realize the dramatic cost-saving benefits of the new Airmo TestMaster® Model 350 Series Hydrostatic Bottle and Cylinder Test Tool.

The TestMaster® Model 350 Series Test Tool solved Piper's serious thread damage problem and product returns with its innovative collet design and self-seating piston actuation technology.

Piper Metal Forming uses a cold forging process to manufacture aluminum oxygen and

carbon dioxide cylinders for the medical industry. Per US DOT compliance requirements, every cylinder that Piper ships must be tested before it leaves their manufacturing facility in New Albany, Mississippi.

Prior to installing twenty-four TestMaster® Model 350 Test Tools, Piper used a manual connector in their hydrostatic testing process that could damage cylinder threads when coupled and uncoupled. Damaged cylinders went undetected because they still passed the hydrostatic test and products were shipped without Piper knowledge. When a Piper customer realized the cylinder threads were defective, Piper replaced the cylinder adding to their manufacturing and shipping expenses.

Kyle Green, Senior Manufacturing Engineer at Piper, and the Airmo design team formed a

strategic working partnership to custom design the TestMaster® Model 350 to meet the needs of Piper's specific

hydrostatic testing application.

Kyle Green, Piper Senior Manufacturing Engineer stated,

"We needed to eliminate thread damage on our oxygen cylinders and we did it. We have not had any products returned since January, 2008.

We significantly reduced our scrap and at the current rate we see a payback on the twenty-four TestMaster® Model 350's in less than two years.

With the reduced scrap and no returns, our production rates should increase as well."

Charles Smida, Airmo Inc. President said,

"It took some trial and error, but in the end we engineered the perfect solution for Piper. Currently, Piper Metal Forming is in the process of adding twenty-four more Airmo TestMaster® Model 350 Test Tools to their carbon dioxide bottle line."

Harry Morán, Airmo COO replied,

"The TestMaster® Model 350 increases production rates, reduces scrap, and improves bottom line performance."

Learn more about the Airmo TestMaster® Model 350 Hydrostatic Bottle and Cylinder Test Tool, contact:

Harry Morán

Airmo, Inc. Pressure Technologies

Phone: +1 (763) 786-0000

E-mail:

harrym@airmo.com

In addition, to a full line of hydrostatic test tools, Airmo also manufactures SelectForm® tube end forming equipment and ExpanTek® tube expansion equipment.

For more information on Airmo's complete line of test tools, systems, and accessories, contact:

Airmo, Inc. Pressure Technologies

Toll Free: +1 (800) 394-0016

E-mail:

airmo@airmo.com

|